JIANGYANG WIND POWER GENERATOR

Main specification

Model |

Rated |

Rated |

Start |

Rated |

Oar |

Oar |

Rated |

Wind |

Wind |

Shelf |

Shelf |

Kit |

Output |

JYF-150 |

150 |

28 |

3 |

6 |

2 |

3 |

400 |

4-30 |

0.38 |

5.5 |

60 |

12v120AH |

Controller |

JYF-200 |

200 |

28 |

3 |

6 |

2.2 |

3 |

400 |

4-30 |

0.38 |

5.5 |

60 |

12v120AH |

Controller |

JYF-300 |

300 |

28 |

3 |

7 |

2.5 |

3 |

400 |

4-30 |

0.4 |

6 |

76 |

12v150AH |

Controller |

JYF-500 |

500 |

28 |

3 |

8 |

2.5 |

3 |

400 |

4-30 |

0.4 |

6 |

76 |

12v150AH |

Controller |

JYF-1000 |

1000 |

28/48 |

3 |

9 |

3 |

3 |

400 |

4-30 |

0.4 |

6 |

89 |

12v150AH |

Controller |

JYF-2000 |

2000 |

48/96 |

3 |

9 |

3.6 |

3 |

400 |

4-30 |

0.42 |

9 |

114 |

12v150AH |

Controller |

JYF-3000 |

3000 |

48/96 |

3 |

9 |

4 |

3 |

360 |

4-30 |

0.42 |

9 |

273 |

12v200AH |

Controller |

JYF-5000 |

5000 |

240 |

2 |

10 |

6.4 |

3 |

200 |

4-30 |

0.42 |

9 |

273 |

12v300AH |

Controller |

JYF-10kw |

10000 |

240 |

2 |

10 |

8 |

3 |

160 |

4-30 |

0.42 |

12 |

325 |

12v400AH |

Controller |

JYF-20kw |

20000 |

240/360 |

2 |

12 |

12 |

3 |

90 |

4-30 |

0.42 |

18 |

325 |

12v400AH |

Controller |

Installation Steps

1. The place choosing

The air blower should be installed in the place that enable wind to fully utilize, and there is no tall and big barrier, make air blower four face the wind, either place oneself in the hill bag, or although the low-lying land in the place, but similar to the corridor, always strong wind strength blows but richly endowed by nature.

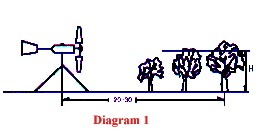

A. If need to install the air blower near the barrier, is far away from barriers as much as possible in conformity with the machine in a situation that the condition is permitted, in order to utilize wind energy fully,(Diagram 1)

|

that is from barrier distance require very much.

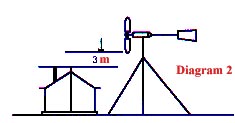

B. If erect air blower on barrier, installation of air blower should make wind wheel go to reason higher than 2 meters of peaks of barrier at least highly.(Diagram 2)

2. Choose installation place, fix pedestal andground anchor with concrete. Ground anchor is 3.6m from pedestal. Three ground anchors are 120° from each other. Begin next step after concrete fixation.

3. Assemble upright stanchion, install rigging.

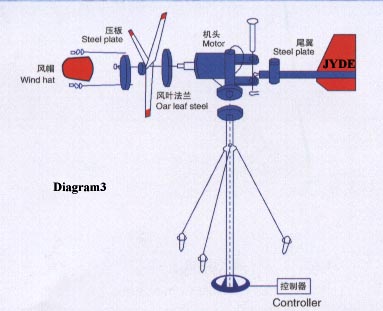

4. Fix generator unit and upright stanchion. (Diagram 3)

|

5.

Assemble blade hub, blade concave surface face the wind, protruding in the face of the electrical machinery, can't is it inside out, put kind blade is it put into electrical machinery axle to become always, oput washer to put, screw M20 nut on. Rotate the blade, it is normal to check the axle of the electrical machinery, hub, the installation water conservancy diversion is put on close the bossing.

6. Fix the empennage girder on the generator's spheriod, install tail vane board.

7. Connect the generator's lead-out wire to the cable, pull the cable out from the spheroid center to the pedestal.

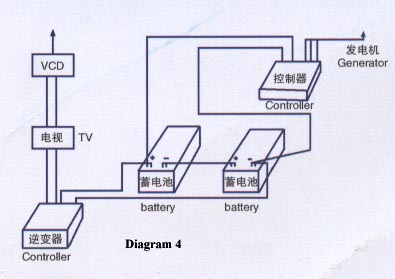

8. Connect the lead-out cable to controller, anode and cathode of the controller to those of the accumulator.(notice: anode to anode, cathode to cathode). refer to (Diagram 4)

9. Customers using inverse sontroller should connect three-phase machine to inverse controller, anode and cathode of the inverse controller to those of the accumulator.

10. Set up the aerator, adjust the position of three screws. Let the aerator be vertical.

Notice:

1. Don't ambulate in the scope of 5m from the bottom of the aerator when it's running.

2. In weather with speed exceeding working speed limits, please fall the aerator down in advance.

Faults and elimination

A No charge

1. The accumulator was charged insufficiently at first use. It should be sent to the accumulator factory to be charged again or replaced.

2. The accumulator is worn out or vulanized, Be replaced.

3. The connection of accumulation is too thin or to be corrupted. The connection cable should be replaced and fixed again to get good contact.

4. Rectifier is worn and should be replced.

5. If commutating inverse controller runs normally.

B No electricity generation

1. Export cable is cut or the cable was worn with short circuit. The cabble should be repaired or replaced.

2. The generator is blocked with no running and should be replaced.

3. The upside and downside of the lamina is installed reversely. It should be removed and installed again.

C Bad timing

1. The rotational part of side framework rusts or dirties. Clean up. The rotational prt should be lubricated.

2. The lamina is worn or unbalanced. Need replacement of adjustment.

3. The tight wire is too loose or too tight. The screw button of CO rigging should be adjusted to get moderate tightness.

4. Upright stanchion is not vertical to the ground. The screw button of CO rigging should be adjusted.